Microwave Medical Waste Solutions for the sterilization and disposal of infectious biomedical waste, is a process that integrates a sterilization system based on the combined action of microwave energy and steam heating, with bulit-in shredder, other treatment devices and software. Solutions and equipment designed for a variety of application scenarios by Li-Ying R&D and manufacturing.

No need for the large amount of steam, water, electricity, wastewater treatment required by autoclave, and high-pressure containers maintained by special technical operators. Li-Ying solutions can provide easier management of automated processes, lower risks, respect for environmental initiatives, and lower operational costs (compared to incineration, autoclaves, and friction).

Medical Waste Disposal Unit - MDU Series (Skid Mounted) is the main series of Li-Ying solutions, integrating automatic feeding, shredding, sterilization, discharging, exhaust gas treatment and other functions in one continuous automatic process, with a capacity of 60kg/h to 800kg/h. And the MOU series is the on-site medical waste disposal system for healthcare institutions.

Liying's Medical Waste Disposal Vehicles and Transfer Vehicles in continuous iteration and upgrading, with treatment capacity varies from 60kg/h to 300kg/h. We have also designed IoT monitoring systems for our customers through RFID, webcam and internet systems.

The convenience and flexibility of the medical waste microwave sterilization vehicle make it a good service for various emergencies, which is plug and play, convenient and fast. It is usually a good service for natural disasters such as sudden epidemics and remote areas, and also for field hospitals, marine and island medical waste disposal, etc.

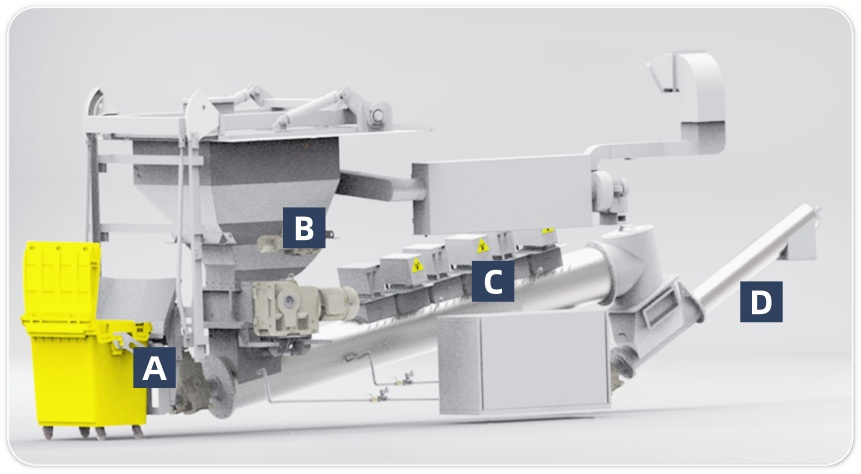

Treatment Process

LiYing MDU and MDV series have integrated shredders. The process of infectious waste disposal includes

a. Lifting the medical waste bin and dumping waste,. b. Shredding the waste into small pieces into the sterilization bin,. c. Microwave and steam action in the sterilization bin to kill microorganisms,. and d, unloading the sterilized waste. Whole process is automated and controlled by one touch.

Low operating cost: Half or less water and electricity consumption compared to other treatments.

Safe: No irradiation risk, or pressure vessel risk, no chemical.

Fully automatic: Reduce your costs and operational risks even more.

Applicable to various healthcare and waste management institutions

Liying's various types of medical waste microwave sterilization equipment are designed and manufactured mainly for hospitals and clinics of all sizes, as well as for service organisations for the collection and centralised disposal of medical waste. It is also capable of handling emergency situations.

Applicable to various Medical and Healthcare Service Institutions, including:

- Hospitals

- Clinics

- Laboratory

- Blood Bank

- Test Center

- Nursing Home

Even some special institutions, like:

- Customs Epidemic Prevention Department

- Field Hospital

- Marine and Island Medical Waste Disposal

Emergency conditions, like:

- Natural disasters such as earthquakes

- Outbreaks of epidemics, etc.

Applicable Range

Liying medical waste microwave disposal equipment is professionally used for the harmless disposal of medical waste, including medical waste that is classified as infectious, traumatic, and pathological waste. It can also be used in epidemics when dealing with sick and dead poultry.

- Blood and Blood Products

- Dialysis Waste

- Animal Tissues, Body Parts, and Carcasses

- Human Tissues, Body Parts, and Limbs

- Biological and Non-Hazardous Pharmaceutical

- Needles, Syringes, and other Sharps

- Research Waste

- Laboratory Specimens

- Surgery Waste

- Regulated Medical Waste

- Pathology and Histology Samples

- Aids and Hepatitis Waste

- Isolation Waste

- Cultures and Slides

- Intravenous Bags, Blood Bags, and Associated Tubing

- Packaging Materials

- Trace Chemotherapy/anti- neo plastic waste

- Soft waste (gauze, bandages, gowns, bedding) from patient care

Mask & other infectious waste

Contaminated fabric waste

Blood & blood products waste

Pathology & laboratory waste

Surgical waste

Needles, syringes & other waste

Why not compare before you choose..

| Compare technologies | LiYing Tech | Autoclave | Incinerator |

|---|---|---|---|

| (Microwave) | (Hot steam) | (Incineration) | |

| Process | Continuous/Batch | Batch | Continuous/Batch |

| Integral shredding | ✓ | X | X |

| Waste volume reduced | ✓ | ✓ | ✓ |

| Installation requirements | Low | High | Very High |

| On-site installable | ✓ | ✓ | X |

| Odor | Low | High | High |

| Noise | Low | High | High |

| Sterilization effect | High | High | High |

| Cost | |||

| Labor costs | Low | High | High |

| Investment costs | Intermediate | Intermediate | High |

| Energy Used | Very Low | High | High |

| Maintenance costs | Low | High | High |

| ROI | High | Low | Low |

| Features | |||

| Environmental Impact | Eco-friendly | Intermediate | Significant |

| Safety | High | Pressure risk | Low |

| Ease of Operation | One-man Operation | Low | Low |

| And more |

|---|

Feel free to contact us for more details !

Final Residue

After treatment by Liying's Microwave Disposal Unit, the waste becomes decontaminated, non-infected, unrecognisable inert general waste, which can then be centrally disposed of as MSW for landfill or used in an incineration power generation project, depending on local laws and regulations and local circumstances.

Medical waste produced by various medical institutions

Various types of medical waste collected

1.After treatment, it becomes inert domestic waste

2.Landfill or incinerate with domestic waste to generate electricity

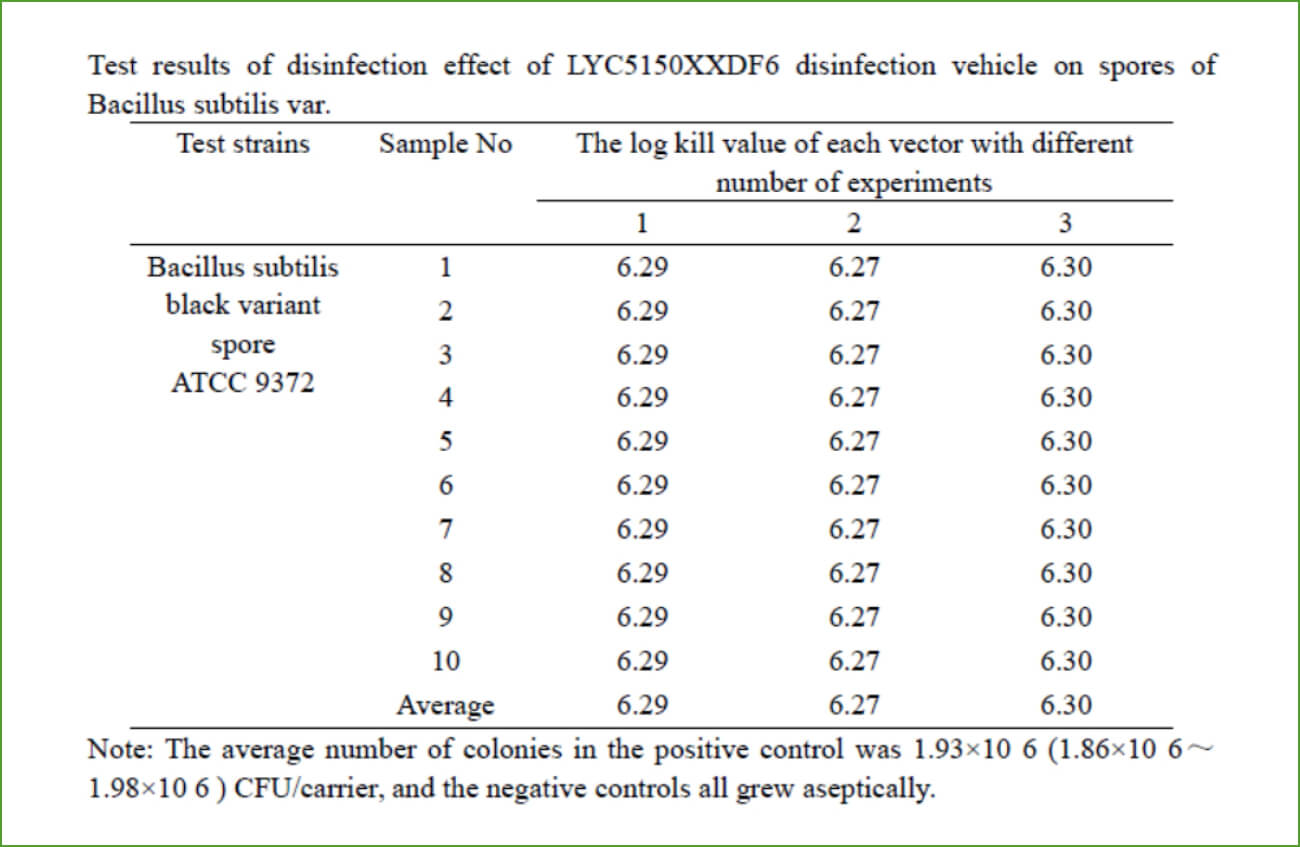

Sterilization Effect Detection

The treatment effect test uses Bacillus subtilis var. niger spore (ATCC 9372) as biological indicator, with killing logarithm value ≥ 4.00. the microbial inactivation efficiency is greater than 99.9999%.

Step 1

Use 3M-1264 biological indicator Bacillus subtilis B. Subtilis ATCC 9372

Step 2

Put the biological indicator into the reserved mouth of the microwave sterilization device

Step 3

Pick up biological indicators from the residue

Step 4

Crush the ampoule, and place the biological indicator and reference group in a 37°C constant temperature incubator for 48 hours

Step 5

Obtain the test result, green means the sterilization effect is qualified, and yellow means the sterilization effect is unqualified

Solutions has a very significant killing effect on the spores of Bacillus subtilis. The results of multiple experiments were very consistent, indicating good reproducibility of the results and very stable and reliable operation of the equipment.

[sg_popup id=4760]