MDU-10pro is a Medical Waste Treatment System, integrated Sterilizer with Shredder. State-of-the-Art Technique and Low operational cost.

Specifications:

MDU-10 Pro Medical waste Disposal Equipment with new upgraded design, materials and integrated steam and microwave sterilization, is used for the biomedical waste disposal. The scope of disposal for medical waste that is classified as infectious, traumatic, and pathological waste. It is also used in epidemics to dispose of sick and dead poultry.

| Equipment Model No. | MDU-10 Pro |

| Treatment Capacity | 800kg/h |

| Dimensions (LWH) | 11,500mm*2,720mm*3,200mm |

| Overall weight | 13,500kg |

| Required space (LWH) | 15,000mm*5,000mm*5,600mm |

| Installed Power | 186KW (108KW steam generator included) |

Standard Configuration

● Microwave and steam combined sterilization system (generators included)

● Built-in shredder

● Auto Lift & Dump and Auto discharge

● Exhaust gas treatment system

● Water purification system

● Microwave leak detector (networking)

● PLC control system with screen

Optional

● Automatic conveyor for continuous feed

● Waste bin continuous batch tunnel Washer

● State-of-the-art robotic arm, touchless process

● IoT Intelligent waste management

● And more customization or OEMs, ODMs.

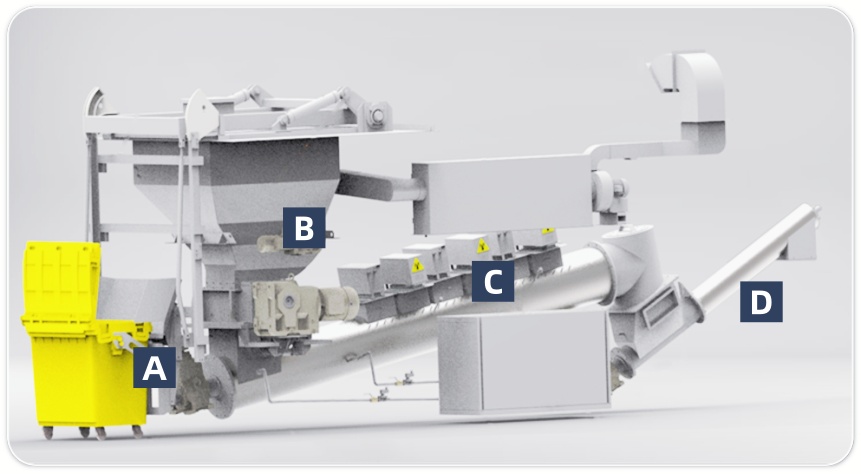

①The infectious material is temporarily held in a waste container(s) which in turn, are emptied into an pre storage hopper via a feeding system which is located at the front of the MDU.

②The infectious waste is fed to the shredding system by a feed arm where it is shredded.

③The shredded material is conveyed through a microwave section and temperature holding section, respectively for disposal, with microwave of 2450MHz (±50MHz), temperature ≥95℃, with over 45 minutes.

④The sterilized and unrecognizable (sharps) waste is then discharged into large waste containers (or compaction units) by the discharging screw conveyor.

From there the material can be transported to a local municipal landfill for disposal or to a refuse recycling plant.

Microwave disposal is the result of microwave thermal effect and biological effect, which can make microwave energy and bacteria directly interact, rapid sterilization.

The thermal effect of microwave energy: Under certain intensity microwave field, the bacteria will be due to the absorption of polarized molecules can increase the temperature of microwave, so that the protein deformation, loss of biological activity. The thermal effect of microwave mainly plays the role of rapid temperature sterilization.

Non-thermal effects of microwave energy: High-frequency electric fields change the polarized molecular structure, resulting in the loss of vitality or death of proteins and physiologically active substances in the microbes, and the special effects of conventional physical sterilization in the sterilization

MDU series products are designed as an automatic operation system with minimal operator operations, with the following characteristics:

[Easy to use] The equipment has a high level of automation, and only one person is required to operate a complete set of equipment. Microwave sterilization requires a small equipment functioning area, doesn't cause high temperatures in the surrounding environment, it's clean and hygienic.

[Environmentally friendly] Microwave heating is uniform, high energy with tiny energy loss, strong penetration, instant penetration into the object, good energy-saving, take the daily capacity of 5 Tons/d model as an example, installed power Only 117 kilowatts. No acid gases, dioxins or other pollutants are produced.

[Absolute sterilization] Microwave can effectively sterilize all materials on all organisms with no select. It has a broad spectrum of sterilization bacteria and can kill various microorganisms and pathogens.

[Save money] Microwave medical waste treatment method is flexible. Free scheduling of startup and shutdown, which minimizes energy loss and personnel wages and saves treatment costs.

| Compare technologies | LiYing Tech | Autoclave | Incinerator |

|---|---|---|---|

| (Microwave) | (Hot steam) | (Incineration) | |

| Process | Continuous/Batch | Batch | Continuous/Batch |

| Integral shredding | ✓ | X | X |

| Waste volume reduced | ✓ | ✓ | ✓ |

| Installation requirements | Low | High | Very High |

| On-site installable | ✓ | ✓ | X |

| Odor | Low | High | High |

| Noise | Low | High | High |

| Sterilization effect | High | High | High |

| Cost | |||

| Labor costs | Low | High | High |

| Investment costs | Intermediate | Intermediate | High |

| Energy Used | Very Low | High | High |

| Maintenance costs | Low | High | High |

| ROI | High | Low | Low |

| Features | |||

| Environmental Impact | Eco-friendly | Intermediate | Significant |

| Safety | High | Pressure risk | Low |

| Ease of Operation | One-man Operation | Low | Low |

Get A Free Quote

Tel:

+86-370-5068088Email:

[email protected]Mob/Wechat/Whatsapp:

Subscribe to our mailing list:

PDF Request