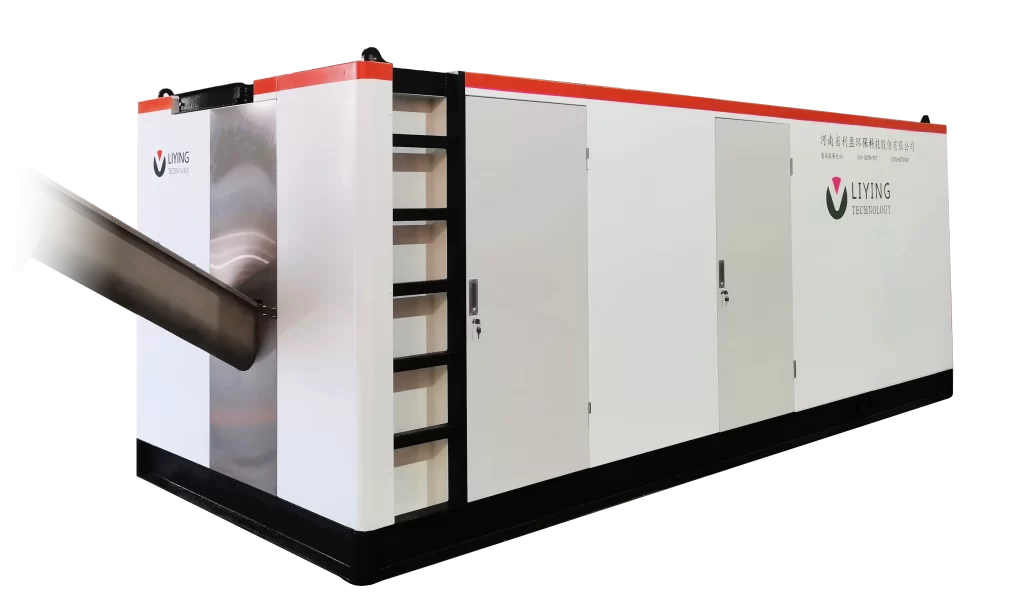

The serie SSE-100 medwaste disposal equipment for hospital is our 2024 new treatment system that utilizes high-temperature steam and microwave to disinfect medical waste; The process of steam+microwave treatment followed by shredding treatment, including process units such as “feeding, pre vacuum, high-temperature steam treatment, drying, discharge, and shredding”.

Specifications:

The SSE-100 is Li-Ying's new fully automated medical waste treatment system that uses high temperature high pressure steam and microwave to sterilize Regulated Medical Waste (RMW), namely medical waste with infection risk. Using a process of disposal followed by shredding. Integrated built-in process units including "pre-vacuum, steam and microwave combined treatment, drying, discharging and shredding".

● Treatment capacity 50 kg/hr.

● One-man operation

● No dioxin emissions

Perfectly suited for disposing of medical waste in large or medium sized hospitals, clinics or any health centre, Customs and Quarantine Departments, etc.

| Model | SSE-100 | SSE-75(Unreleased yet) |

| Processing capacity | 25 kg/cycle, 50 kg/hr | 15 kg/cycle, 30 kg/hr |

| Power | 52Kw | 36Kw |

| Dimensions (L*W*H) | 556cm*202cm*200cm | 430cm*180cm*175cm |

| Treatment type | High temperature steam and Microwave sterilization | |

| Sterilization effect | log6 (Bacillus subtilis var. niger, ATCC9372) | |

| Power supply | Three phase five wire AC380V | |

| Working Pressure: | -0.09~0.24MPa | |

| Sterilization temperature | 134℃~138℃ | |

| Sterilization Cycle | 30min | |

| Weight | 6.5t | 3.5t |

Standard Configuration

● High temperature steam and microwave combined sterilization system

(including steam generator and microwave generator)

● Built-in shredder

● Exhaust gas treatment system

● Water purification system

● Microwave leak detector (networking)

● PLC control system with screen

Optional Configuration

● Automatic Feeding Unit

● And more OEMs, ODMs.

The principle of the pressure steam sterilisation process is the penetration of pressurised steam into the interior of an object. It causes microbial proteins to coagulate, denature and die, and it enhances the efficiency of microwave sterilisation. The treated medical waste is sent to sanitary landfills or incinerated. This method is also suitable for sterilising contaminated overalls, syringes, dressings, microbiological media, etc.

The SSE-100 treatment process includes medical waste feeding, high-temperature steam sterilization ,Drying, Shredding, Unloading with Wastewater and exhaust gas treatment.

Easy transportation and installation with an integrated design.

High degree of automation, single person operation, after the medical waste being poured into the hopper, the equipment automatically completes whole procedures of medical waste treatment

Low cost still top efficient. Low water content in the treated medical waste, because of a vacuum drying technology.

In whole processing of the sterilization of medical waste. shredding is a key procedure. Shredder of the MDU-SSE series equipment adopts a low speed, high torque dual drive hydraulic motor.

Get A Free Quote

Tel:

+86-370-5068088Email:

[email protected]Mob/Wechat/Whatsapp:

Subscribe to our mailing list:

PDF Request